VIDEO Coping with Crown Moulding and Trim

July 27, 2021 | Guest Author

By Aaron Butt, M.T. Copeland

A coped joint is used to join inside corners of crown moulding. A coped piece of trim is cut so the profile on one end fits snugly against the other piece. These pieces fit together like a puzzle, allowing for a tight fitting joint even if the corner is not a perfect 90 degrees or if the ceiling is not completely level to the wall.

Coping a corner will ensure a tight fit with out-of-square corners and ceilings. The ability to hide irregularities and join corners quickly is why most professional builders cope crown moulding instead of mitering inside corners. Coping crown moulding can seem like a daunting task, but rest assured—it’s a carpentry task you can master.

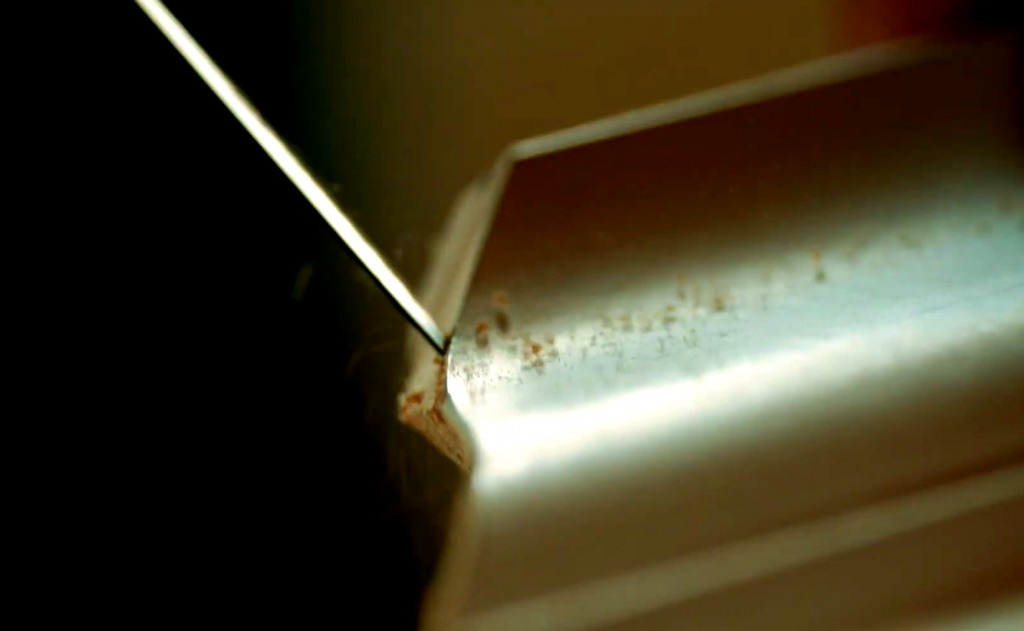

In cutting with a coping saw there are two important things to keep in mind. First: you need to make relief cuts. As you can see in the accompanying video, if you’re cutting into hard turns like in this chair rail moulding, the saw is not going to have an easy time making that turn as it cuts. The sawblade could bind up.

I make a straight relief cut to the top of the turn, so that I only need to cut half of that profile with the saw. Then I can back in the other direction and cut it back the other way. It makes it a little easier to get the work done.

The second thing—and this is actually important with whatever tool you choose to cut your copes—is to make a back cut into all of the material so when it intersects with the other piece of moulding there’s nothing to get in the way of those profiles meeting perfectly.

When I approach the cut with a coping saw, I make sure to give myself enough room to maintain that back cutting angle the entire time I’m cutting the piece. I also like to leave a bit of material so I don’t accidentally overcut. In these cases, I’ll come back and finish with a file.

When you’re setting up to cope carefully mark out the profile line of that piece of moulding. The provides a solid visual as to where you’re going to stop your cope so you can be more precise.

Aaron Butt teaches courses at M.T. Copeland, and has been in the trades for more than 20 years, primarily in the custom, high-end architect-driven building market on the north shore of Boston. He is passionate about excellence and the craft of custom residential building. Having also spent time teaching a full-time carpentry program at the North Bennet Street School in Boston, Butt fully embraces his desire to continue teaching what he knows and learning from others who have gone before him.

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM

Friday

8:30 AM–2:00 PM

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313